USEFUL TIPS

ABOUT PAINT PRODUCTS

-

WHAT PAINTS ARE USED FOR

WHAT PAINTS ARE USED FOR -

Paint can be defined as a mixture of chemical compounds intended to form a film with sufficient mechanical and physical strength to protect the painted surface from external agents over time. Paint is used both to protect and decorate.

These products are used in almost all stages of boat painting: preparation, priming, protection and finishing. Although no paint is used during preparation, getting this stage right ensures the ultimate success of the job. Poor preparation usually means disappointing results. The next step after preparation is applying the primer. The primer protects the substrate and also guarantees that successive protective layers and finishe will adhere to the surface, avoiding delamination. After primer application, the undercoats provide a protective layer, which prevents water, humidity and atmospheric agents from coming into contact with the surface and causing it to deteriorate (metal corrodes, wood rots and GRP suffers from osmosis).

A protective layer with a minimum thickness of 300-600 microns (when dry) for submerged parts and 250-350 microns for areas above the waterline is required to ensure sufficient protection.

The final step is to apply the finish. These products are used to improve the appearance of the boat and the surface properties of the materials used (colour, gloss), or to provide specific protection (antifoulings). For a perfect finish, the surface may need filling to obtain a smooth substrate. To achieve a good enamel finish, the application of a basecoat is recommended, which provides a protective barrier and also a smooth surface, eliminating rough spots left by the filler.

-

WHAT THEY CONTAIN

WHAT THEY CONTAIN -

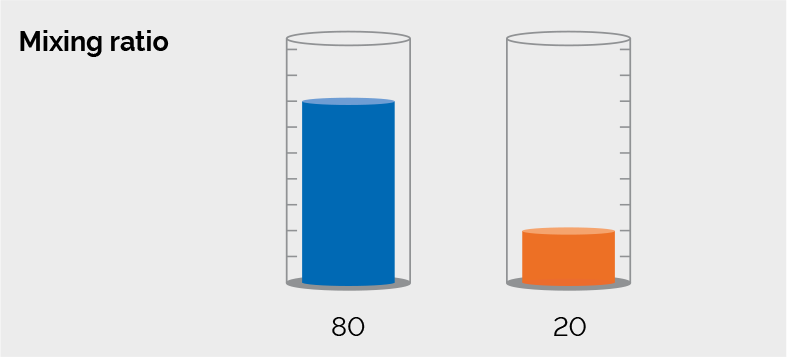

Paints have four main constituents: binders, solvents, additives and pigments. The main component is the binder, which consists of polymers or resins that form a tough, dry film adhering firml to the substrate. Solvents are volatile liquids used to dissolve and disperse the other components. At the same time, by reducing the viscosity of the paint, they make application easier. The evaporation of the solvent controls the cross-linking of the binder and therefore the formation of a uniform film, which is why the correct use of thinners is so important. For environmental and safety reasons, the use of solvents is being reduced or eliminated, with liquid resins used in their place. Pigments are micronised powders that give the paint its colour, hiding power and other special characteristics, such as the antifouling properties of pigments based on copper or zinc salts. Additives are components used in small quantities to improve the properties of a paint (drying, resistance to ultraviolet light, ease of application, pot life, etc.).

-

HOW THEY ARE CLASSIFIED

HOW THEY ARE CLASSIFIED -

Paint products are categorised as varnishes, paints and enamels. Varnishes are transparent and mainly consist of binders, solvents and additives, with no pigments. They are generally used to protect and improve the appearance of the substrate (wood, kevlar, carbon fibre). Paints also contain pigments and/or extenders that give them hiding power and are called enamels when they have particular characteristics such as gloss and resistance to weathering. Fillers are paint products too, characterised by a high percentage of extenders so that they can be used to level cavities and imperfections in the surface. There is an important difference between one pack and two-pack paints. One-pack paints have only one component and the film is formed by the evaporation of the solvent. While these products are easier to apply, they have limited durability. Two-pack paints require mixing in a specific ratio. Filming occurs by means of chemical cross-linking of the two components. This process produces longer durability and better protection.

-

HOW THEY ARE APPLIED

HOW THEY ARE APPLIED -

When you are planning to paint, always remember the following guidelines, which will ensure your safety and prevent you from making mistakes.

- Mask the edges of the area to paint using adhesive tape. Always remember to remove the tape immediately after the application of each coat, especially when using two-pack paints.

- Only dilute as required using the recommended thinner.

- After opening the can, ensure that the paint is evenly mixed to obtain a uniform consistency and colour, especially if the pigment (at the bottom) has separated from the binders (at the top).

- If you are using a two-pack paint, it is important to mix the two components separately before pouring component B (hardener) into component A (base) and then mixing until the colour is uniform. When you are preparing a two-pack paint, take into account how much paint you will be able to use before it becomes unusable (pot life).

- Comply with the recommended drying times even if the paint appears to be dry.

- Apply the paint at a temperature of between 15 and 25°C and a humidity of less than 75%. It is possible to work at higher or lower temperatures than these but you must expect the drying characteristics to change.

- Remember to take into account the temperature throughout the entire cross-linking period, especially overnight.

- Never paint in full sunlight. If necessary, create shaded areas using tarpaulins. Do not paint in strong winds or misty conditions.

- Do not change the ratio between the base and the hardener in two-pack paints because this will alter the chemical characteristics of the product.

- If you are unsure of the paint previously used, it may or may not be compatible and we therefore recommend painting a small test area first. Should any problems arise (cracking, bubbles, "bleeding" or softening of the previous paint), please contact Veneziani Yachting. Normally, you simply need to apply a coat of suitable sealer.

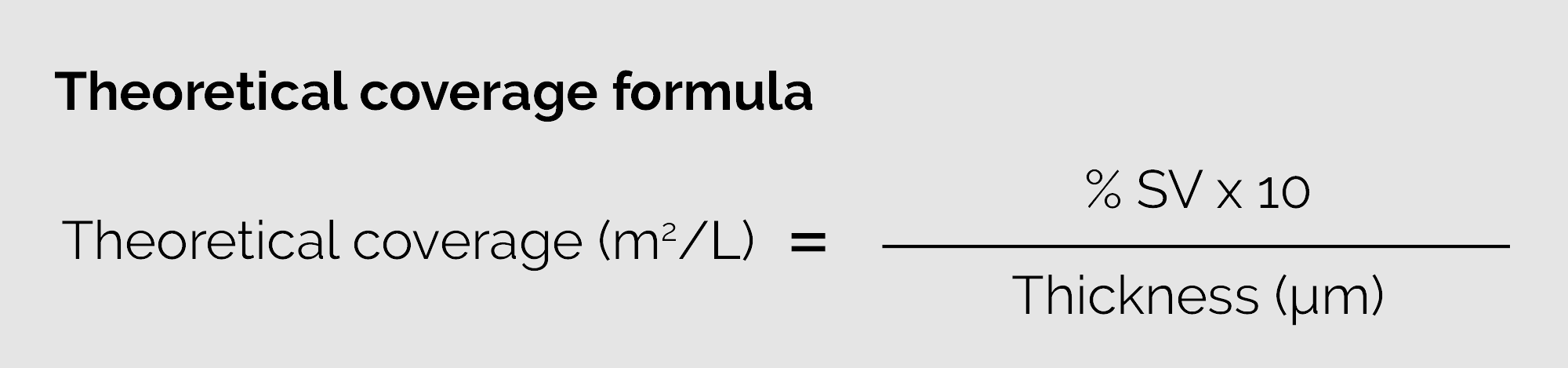

- To check the evenness of the paint, use a paint thickness gauge at various points to measure the thickness of the wet paint “coat by coat” before the solvent evaporates. If the dry paint volume is 100%, the dry and wet thickness will be equal; if it is 50%, the dry thickness will be half as much.

-

HOW TO OPERATE IN SAFETY

HOW TO OPERATE IN SAFETY -

These basic hygiene and safety rules are always applicable when applying paint to boats

- When handling cans over two litres, always check their weight as they may cause back injury when lifted.

- Carefully read the instructions printed on the can before starting to paint.

- Check the safety label in particular for any special precautions that must be taken for each product.

- If the necessary documentation is not available, please consult the website www.venezianiyachting.com.

- Certain paint components (particularly in antifoulings) cause irritation if touched, are harmful if inhaled, and are sometimes toxic. These risks, which vary from product to product, are clearly indicated by the symbols on the safety label, along with any special precautions.

- Do not smoke during application.

- Do not use compressed air to clean your clothes, especially if solvents are present.

- Almost all paints contain flammable solvents which evaporate during drying. Be careful not to inhale the vapours, especially in a closed environment. Ensure adequate ventilation to avoid the risk of fire or explosion and use an appropriate mask.

- We advise wearing gloves, a mask and protective goggles.

- Always sand using wet sandpaper on a wet surface, particularly with antifouling products, and wear gloves, a mask and protective goggles.

- Use a water-based paint stripper if possible to remove old paint, like AQUASTRIP from the Veneziani range. Dry sanding or flame cleaning should be used only where it is impossible to employ a different method.

- When you have finished work, or when taking a break, thoroughly wash your hands with soap and water or a hand cleansing agent. Never use solvent-based thinners or strippers to wash your hands.